Technology

Lower heat source

Available VATRA heat pumps:

- ground heat pumps

water heat pumps

Ground heat pumps

Water heat pumps

Horizontal ground collector

A horizontal ground collector is made from horizontally placed polyethylene pipes filled with aqueous solution of glycol at 1.4-1.5 m below the ground level. The solution of glycol, whose circulation is forced by the lower heat source pump, heats from the ground and transports the heat taken to the heat pump. Heat is taken from brine (cooling) in the heat pump evaporator.

- cheap and reliable

source of heat

- it requires area free

from permanent development, trees

- the size of the

collector sewer depends on the size of the heat pump and ground quality

- the

size of the

collector should be 3 times larger than the area

of the heated building

Vertical ground collector

A vertical collector is made from vertical polyethylene pipe sections inserted in wells and connected at the bottom by a U-fitting. Individual wells are interconnected into loops. Horizontal sections connecting the wells must be placed AT 1.4-1.5 m underground. The space between the wells must be 4.0-8.0 m. The most frequent well depth is about 100 m.

A vertical ground collector needs much less construction place than the horizontal collector. This solution is recommended in particular for heat pumps whose heating power exceeds 50 kW

Deep water well

Waste heat

Waste energy as a result of technological processes is the most effective lower heat source. The necessity of cooling and heating at the same time is frequent in manufactures. The use of a heat pump allows for supplying energy for heating and cooling processes operations.

Construction of a heat pump

VATRA heat pump is equipped with a very effective scroll-type hermetic compressor. It has a solid casing insulated to provide quiet operation. R407C cooling factor is responsible for the thermodynamic circulation. The thermodynamic circulation is implemented via R407C cooling factor. The evaporator and condenser are produced as plate exchangers soldered with copper, with AISI316 stainless steel plates. They are PZH attested. Moreover, VATRA Compact Heat Pump is equipped with a 200 dm3 stainless steel hot usable water reservoir, a valve switching into heating and hot usable water preparation, circulating pumps of cooling and heating parts, safety groups of tap and heating water, 2/4/6kW electric immersion heater as well as the compressor soft start module. The whole heat pump cooling system, in which the compressor, heat exchangers, liquid tanks, pipelines and other elements, is developed on a special load-bearing structure. The lids and casing door are fastened to the casing frame by means of screws. Pipelines and heat exchangers are thermally insulated to limit heat losses and avoid water condensation. Special polyurethane acoustic sheets have been used to muffle the noise caused by the work of the compressor. Vibro-isolation alloys, which fasten the pump to the ground, are fixed to the basis of the casing.

Projekty niestandardowe

Vatra Logic ® automatic control

- on/of button with indicators signalling the heat pump work

- 240 mm × 64 mm graphic display

- buttons of control, operation and help buttons for the control menu

- ground collector,

- deep water wells – in direct and indirect system,

with a heat exchanger,

- boiler room with a heat pump – in five systems,

depending on the configuration of the whole installation system,

- hot usable water with circulation and disinfection –

in four configurations,

- solar system for hot usable water production,

- three variants of radiator heating system: without a

blender, with a blender, without central heating circulation pump,

- three variants of floor heating system: without a

blender, with a blender, without central heating circulation pump,

- swimming-pool water heating system,

- two variants of fan coil cooling system: with or

without a blender,

- two variants of additional heat source system with and without a division of central heating parameters.

Moreover, VATRA Logic plus® enables the communications with the heat pump by means of a GSM module which serves to notify technical services about any failure of the system operation as well as to change the setting by the user.

The automatic control of VATRA Logic plus® heat pump may cover thirty two working modules and serve all possible heating and cooling installation types.

Setting performed by the user:

2. Programming usable hot water temperature and usable hot water circulation:

- according to the schedule, each day is and individual option, from

Monday to Sunday

- option to program a momentary temperature.

3. Programming parameters of usable hot water thermal disinfection:

- turning on/off and disinfection frequency – overheating usable hot

water reservoir to 70°C,

- disinfection starting time and its duration.

4. Programming thermal comfort:

- according to the schedule, each day is and individual option, from

Monday to Sunday, from Monday to Friday, Saturday and Sunday as well as

holidays. 24 hours are divided into seven time zones.

- standard temperature

- weather algorithm of heating and cooling,

- holidays with an option of introduction of two time periods.

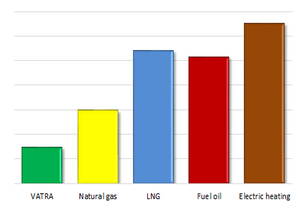

Cost analysis

Annual costs of heating a 200 m² one-family house with various energy carriers.

Looking for more information?

Contact us and we'll help you to other solutions. We help raise funds for realization the installation.

Specialists

FAQ

What is the warranty coverage of the Vatra heat pump?

Odpowiedź

How often do I have to do the installation service?

Odpowiedź

Do you need to replace the glycol in the system?

Odpowiedź

How big should I have a building to be able to install a heat pump?

Odpowiedź

How do I order a service to the pump? What is the waiting time?

Odpowiedź

What type of heating used in the home, to heating heat pump was the most efficient and cost?

Odpowiedź

Are there any special permits required for the use of heat pumps as a heat source?

Odpowiedź